Introduction:

Clean and well-maintained hood filters are crucial for the efficient operation and safety of commercial kitchens. This case study explores the effectiveness of the DECARBONATOR®, a specialized cleaning system designed to remove hidden Fats, Lipids, Oils, and Grease (FLOG) from hood filters that conventional cleaning methods may leave behind.

Background:

In any commercial kitchen, the presence of FLOG in the air can lead to a variety of issues. FLOG particles can coat surfaces, including floors, posing a significant slip and fall hazard. Additionally, FLOG buildup can cause the HVAC system to work harder, leading to increased utility expenses. Conventional cleaning methods, such as manual scrubbing and using a 3-Compartment Sink or Dishwasher, may not effectively remove all FLOG, especially from the baffles inside hood filters.

Objective:

The primary objective of this case study was to determine the effectiveness of the DECARBONATOR® in removing hidden FLOG from a hood filter compared to conventional cleaning methods.

Methodology:

A hood filter from a commercial kitchen was selected for the study.

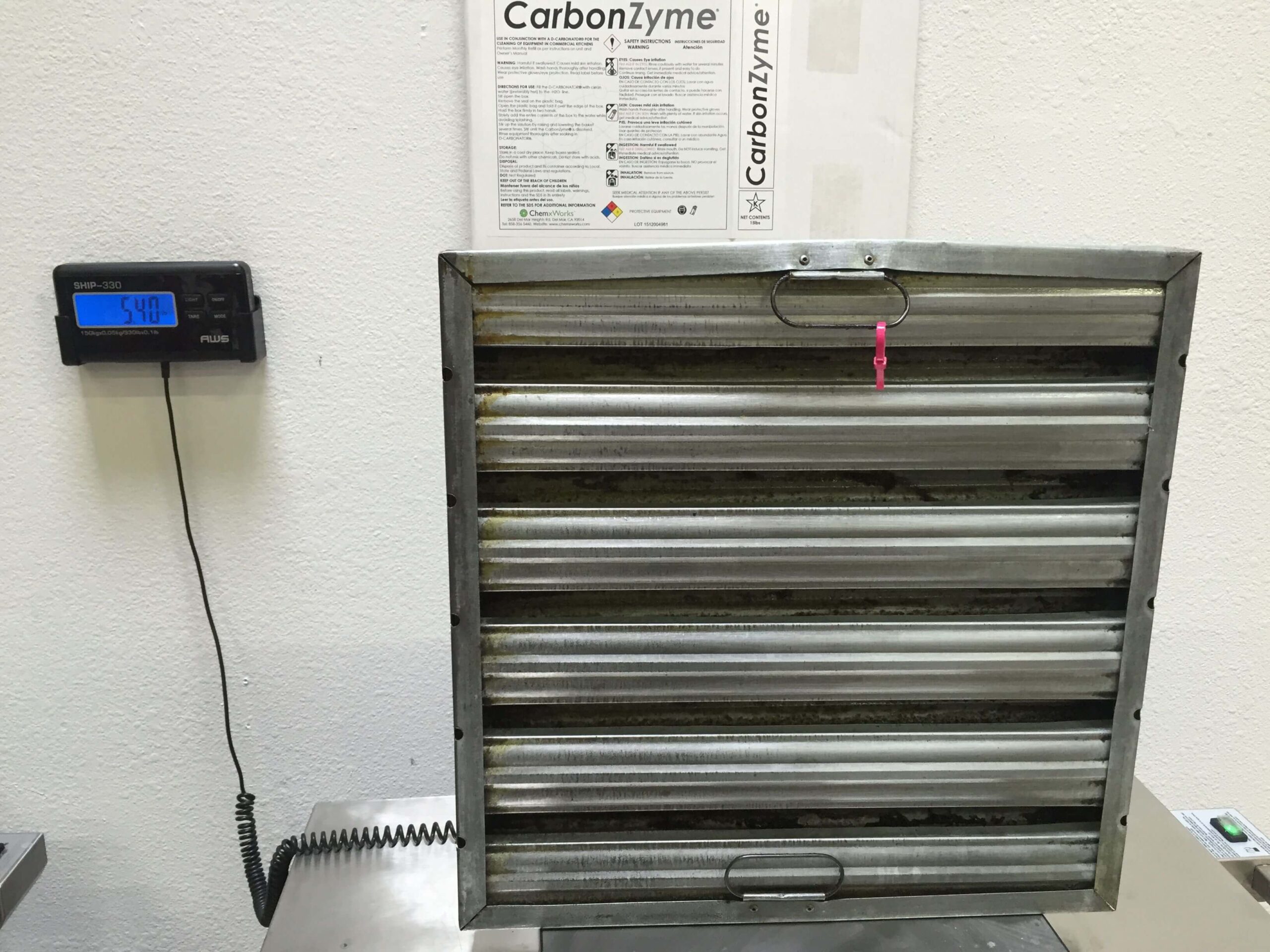

The initial weight of the hood filter was recorded before any cleaning.

The filter was subjected to a conventional cleaning method, which involved soaking it in a hot water solution of degreaser and manual scrubbing for 15 minutes.

After the conventional cleaning, the filter was weighed again to assess how much FLOG was removed by this method.

The same filter was then soaked in the DECARBONATOR® for a specified duration of 30 minutes.

After the DECARBONATOR® cleaning, the filter was weighed again to determine the amount of additional FLOG removed.

Results:

The results of the study are as follows:

Initial weight of the hood filter: [7.94 lbs]

Weight of the filter after conventional cleaning: [7.72 lbs]

Weight of FLOG removed by conventional cleaning: [.22 lbs]

Weight of the filter after DECARBONATOR® cleaning: [7.5 lbs]

Additional FLOG removed by DECARBONATOR®: [.22 lbs]

Discussion:

The study revealed that the DECARBONATOR® was highly effective in removing additional FLOG from the hood filter. This is a significant finding because conventional cleaning methods left behind a substantial amount of hidden FLOG, as evidenced by the increase in filter weight after DECARBONATOR® cleaning. This hidden FLOG could lead to safety hazards and increased HVAC energy consumption if not properly addressed.

Conclusion:

Based on the results of this case study, it can be concluded that the DECARBONATOR® is an efficient and cost-effective method for cleaning hood filters. It not only removes visible FLOG but also tackles the hidden FLOG within the baffles of the filters. By using the DECARBONATOR®, commercial kitchens can maintain a safe environment, reduce slip and fall risks, and save on utility expenses, all while minimizing labor and maintenance costs.

Commercial kitchen operators are encouraged to consider incorporating the DECARBONATOR® into their hood filter cleaning routines to ensure a clean and safe kitchen environment.